LANXESS e-mobility

LANXESS offers a broad product portfolio for electromobility. From raw materials and specialty chemicals for battery materials to dyes for high-voltage applications, flame retardants for high-performance plastics and cooling fluids for battery systems as well as components of the electric powertrain components comprehensive innovations from a single source.

e-mobility - our way into a sustainable future

Climate change is one of the most significant challenges the world is facing today. LANXESS takes its responsibility and is committed to become climate neutral by 2040.

A transition towards sustainable and smart mobility offers many opportunities for CO2-savings. Lithium-ion batteries as the heart of electric cars are the key technology towards zero emission vehicles. The demand for batteries is growing rapidly, providing vast opportunities for the chemical industry to develop innovative materials.

LANXESS offers material solutions for lithium-ion batteries and e-mobility applications - to contribute to future mobility needs.

BATTERY MATERIALS

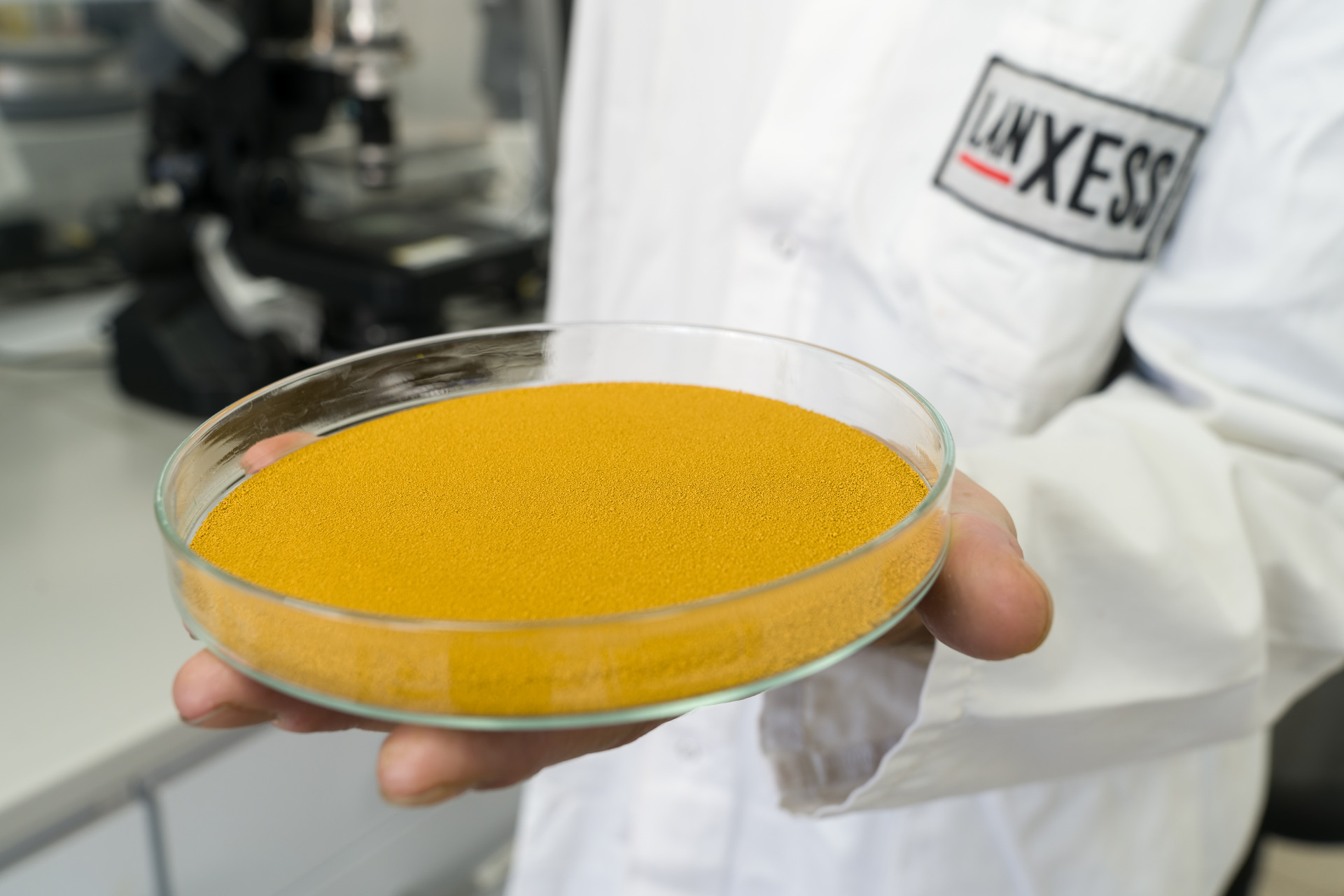

Advanced lithium-ion battery technology is strongly material driven and major improvements account to innovative materials and processes developed by the chemical industry. LANXESS offers a broad range of advanced materials and technologies for lithium-ion batteries.

Our product portfolio for battery materials comprises raw materials and precursors for cathode materials and electrolyte components as well as refining technologies for lithium, cobalt and nickel.

LANXESS is energizing chemistry

LANXESS has a strong platform for battery materials. Our upstream integration into key raw materials and existing asset footprint in Europe have the potential to strongly contribute in creating a local battery material value chain to enable a sustainable cell production in Europe.

SOLUTIONS FOR BATTERY SYSTEMS & E-POWERTRAIN

MORE ABOUT THE TOPIC E-MOBILITY

Why LANXESS?

For us quality is the individually perceptible sum of premium character, workmanship, service and emotional desire.

We are a resilient global supplier that provides our customers with value-added components, solutions and raw materials. We enable you to optimize the attributes that translate directly to value for your applications and businesses. Quality is also infused into every part of our operations: expertise, friendliness, reliability, corporate citizenship, and a strong focus on solutions. As a responsible supplier, we are focused on staying ahead of regulations, ensuring our suppliers to meet our sustainability standards, supporting our communities, and driving leadership in sustainability - being climate neutral by 2040.